The HF oil Storage systems have been created for their correct management, offering a varied proposal of

world-class solutions developed with the strictest quality standards.

These systems are interrelated to establish the best oil management practices, adjusting service time, limiting

bulk storage, facilitating oil cleaning, avoiding cross contamination in use, offering better safety conditions and

contributing to the environment.

HF systems allow management directly from the oil drum to storage in their tanks and can incorporate

automatic control that allows the traceability of the operation and increases the quality of management.

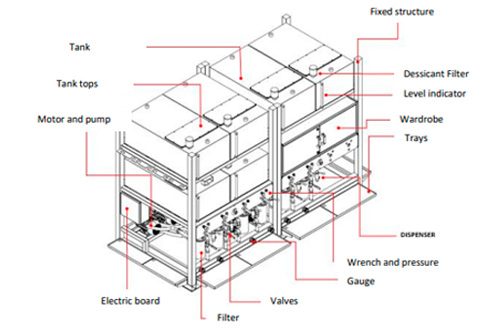

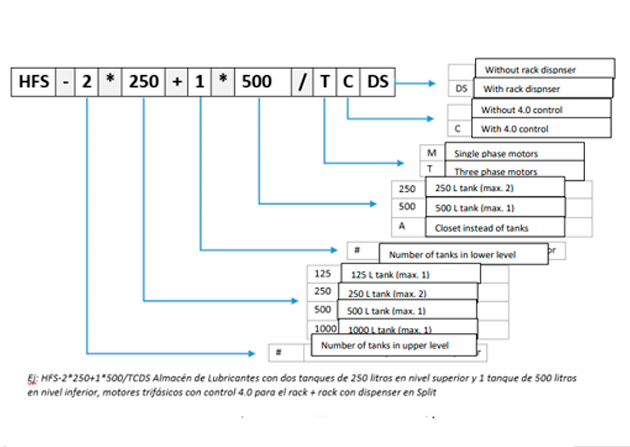

Oil storage systems can be configured according to management needs, with tank sizes of 125l, 250l, 500l and 1000l.

It can be ordered with or without a tool cabinet when no more tanks are needed.

It allows the incorporation of additional and ergonomic service racks for the storage of lubrication elements.

It can be ordered with automatic control OLS V1.0 for user management, control of liters and times. One control can handle up to 12 tanks in two Racks.

Each Rack supports the command of up to 6 tanks (2 of 250 liters and 4 of 125 liters) and combine up to 8 colors.

| Dimensions per rack | Tension | Stream | Pump | Motor | Particles Filter | Desiccant Filter |

|---|---|---|---|---|---|---|

| Width: 1400 mm Height: 2300 mm Deepth: 1200 mm |

Optional 220V 380V |

Máx.: 16A (depends on the number of motors running simultaneously) |

20 lts/min (up to ISO 220) 10 lts/min (up to ISO 680) |

1HP 1000 rpm | Optional 3 microns 5 microns 10 microns |

HF-2 (250 gr of silica gel) |

Contact us. We provide professional and personalized counselling on all our products and services.