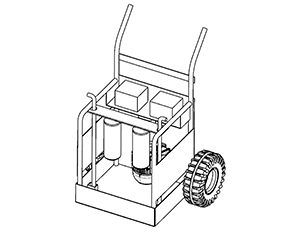

The mobile HF filtration equipment allows flushing, filtering and transfer of oil from machinery or hydraulic equipment.

The system works by circulating the fluid by means of a pump passing through filters in series that remove the particles to achieve the appropriate ISO quality.

Some of our models allow the speed of the motor to be varied, suitably adapting to the different viscosities of the fluids and types of equipment to be filtered.

The motor is protected by vacuum aspiration or electrical overloads that could damage it.

TROLLEY: robust and durable Allows long service life. Inflatable wheels * that allow good accessibility.

HIGH EFFICIENCY: Cost recovery by effective filtration with pressure filters for two filtration stages - coarse / fine or particulate / water.

PROTECTION: protection against electrical overload and speed variation * for different filtering times

| Model | Dimensions | Tension | Stream | RMP | Flow | T° operation | Viscosity Máx. |

|---|---|---|---|---|---|---|---|

| HFF-C1-F#/M | 100*55*40 cm | 220v | 10 A | 3/4HP 1500 rpm | 32 lts/min | -25°C a 70°C | Up to ISO 220 |

| HFF-C1-F#/T | 100*55*40 cm | 380v | 10 A | 3/4HP 1500 rpm | 32 lts/min | -25°C a 70°C | Up to ISO 220 |

| Model | Dimensions | Tension | Stream | RMP | Flow | T° operation | Viscosity Máx. |

|---|---|---|---|---|---|---|---|

| HFF-C2-F#F#/M | 130*55*40 cm | 220v | 10 A | 1HP - 1500 rpm | 32 lts/min | -25°C a 70°C | Up to ISO 220 |

| HFF-C2-F#F#/T | 130*55*40 cm | 380v | 10 A | 1HP - 1500 rpm | 32 lts/min | -25°C a 70°C | Up to ISO 220 |

| Model | Dimensions | Tension | Stream | RMP | Flow | T° operation | Viscosity Máx. |

|---|---|---|---|---|---|---|---|

| HFF-C3-F#F#/M | 130*55*40 cm | 220v | 10 A | 1HP - 900 rpm | 5 a 32 lts/min | -25°C a 70°C | Up to ISO 680 |

| HFF-C3-F#F#/T | 130*55*40 cm | 380v | 10 A | 1HP - 900 rpm | 5 a 32 lts/min | -25°C a 70°C | Up to ISO 680 |

| Model | Dimensions | Tension | Stream | RMP | Flow | T° operation | Viscosity Máx. |

|---|---|---|---|---|---|---|---|

| HFF-C4-F#F#/T | 130*55*40 cm | 380v | 10 A | 1HP - 1500 rpm | 32 lts/min | -25°C a 70°C | Hasta ISO 680 (con variador) |

When the filter cart is used for off-line filtration, the oil will have to pass through the filters approximately 8

times to achieve the cleanliness levels according to the micron size of the installed filters.

The following formula is used to calculate the amount of time required to achieve optimal cleaning.

(Tank size (lts) x 8) / (flow (lts / min)) = Time (minutes)

To achieve greater precision of the desired cleaning codes, it is recommended to operate our equipment with contamination sensors.

Contact us. We provide professional and personalized counselling on all our products and services.